Process Copy

Industry Leading

Engineering

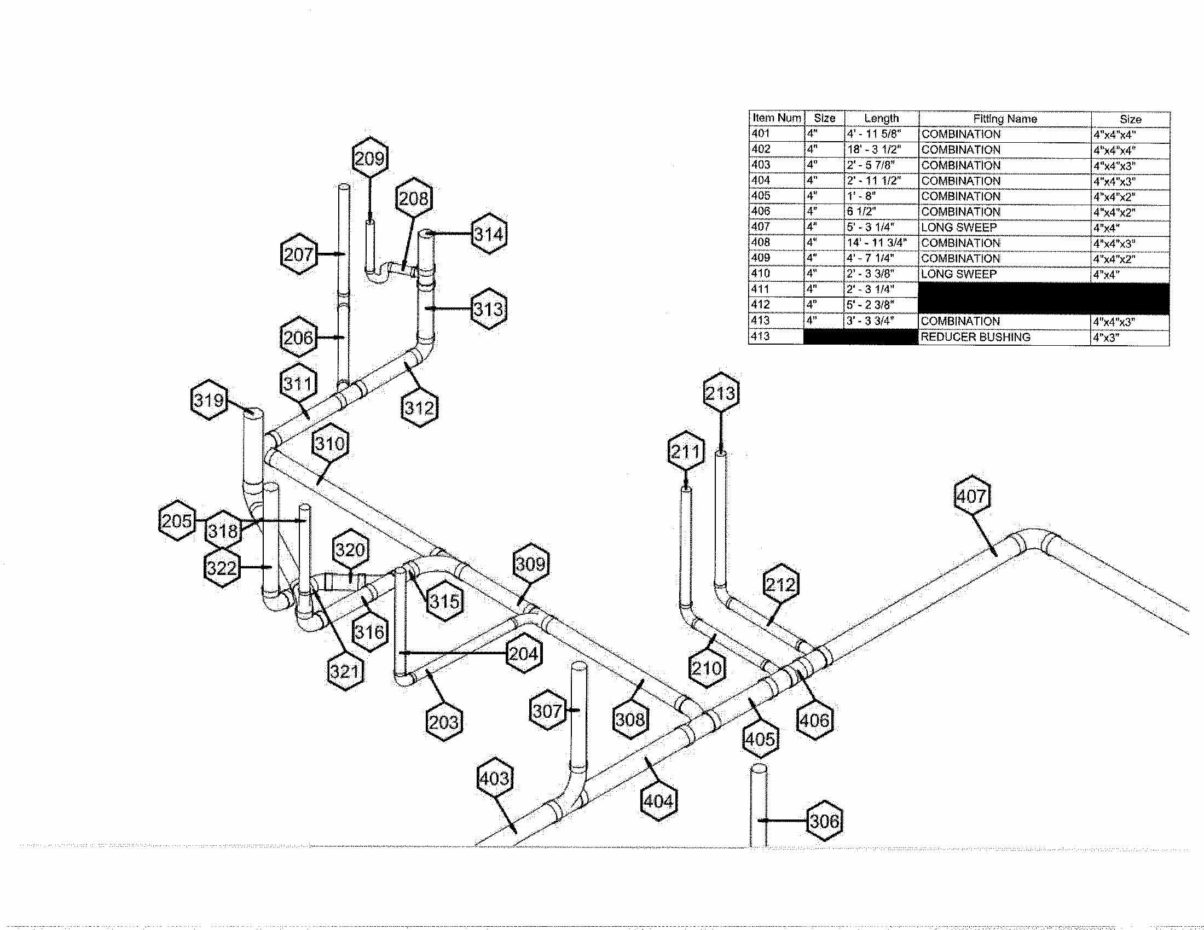

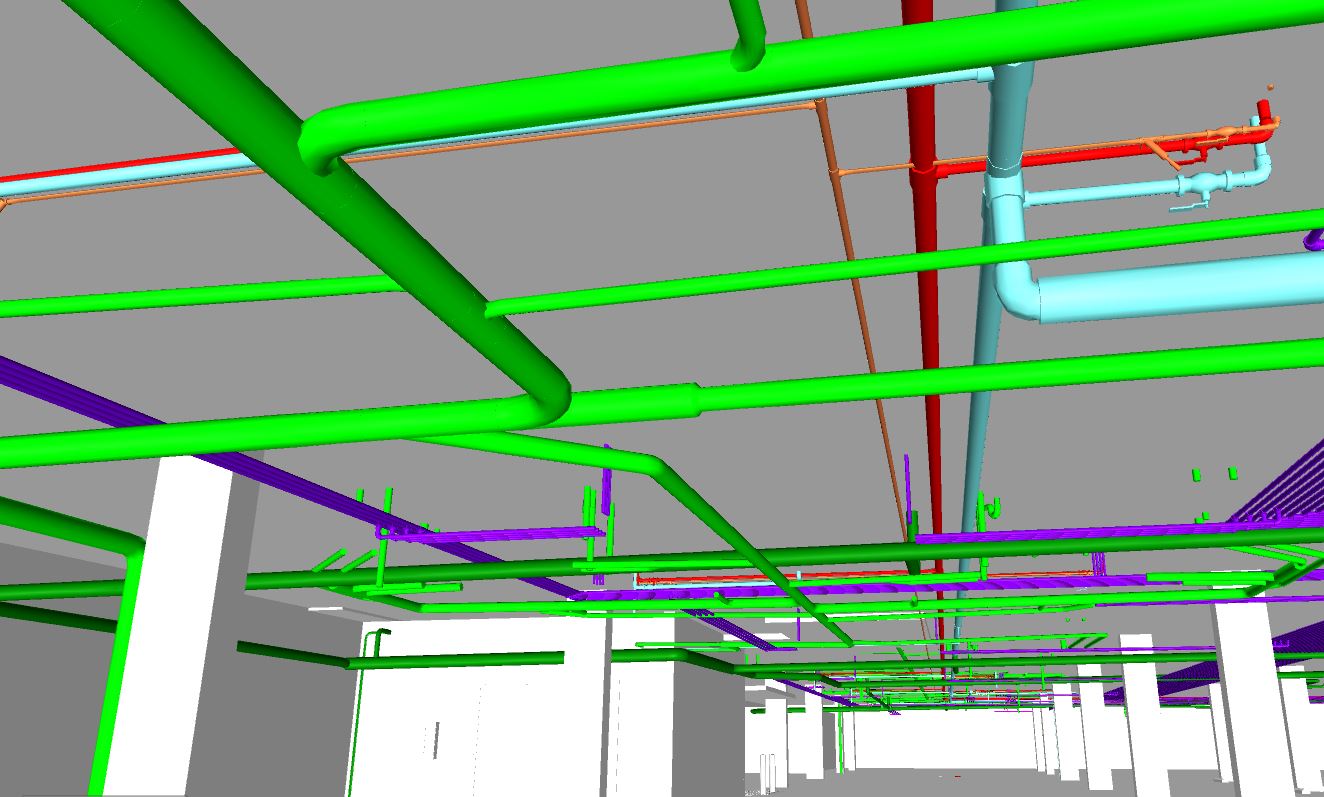

Our plumbing engineers manage the engineering process across the entire life cycle of the Design/Build process from initial design (Design) through construction (Build). The senior plumbing engineer on a project is the Job Captain who is responsible for all engineering deliverables across the entire Design/Build project including plumbing plans (P-Sheets), Building Information Models (BIMs), Isometric drawings (ISOs), list of materials on each ISO (Cutsheets) and the project’s entire Bill of Material (BOM). These engineering deliverables are completed for all of the project’s waste, storm, vent, water and gas integrated systems.

We utilize a Design/Build marketing strategy to establish a mutually beneficial relationship with our customers. Our integrated Design Engineering / Construction Engineering team is the first step in our Design/Build process. Each project starts with a plumbing engineer/modeler team who creates plumbing system drawings and 3-dimensional models necessary to create ISOs and Cutsheets that facilitate the optimal fabrication and installation efforts for the project.

We are skilled in several design software systems including 2 and 3 dimensional CAD and Revit and specialize using the Revit application for BIM maximization throughout the entire design and construction integrated engineering process allowing for overall assimilation of our work into our client’s design team requirements. Our Design/Build Engineering team works to review plans, client’s requirements and code requirements working within existing processes in place by our clients to facilitate changes.

We work closely with our client’s team of design staff and building department officials to facilitate the ideal Design/Build process by designing plumbing systems in which the waste, vent, storm, water and gas systems synchronize with Structural, Civil, Site Utility, Mechanical, Landscape and Architectural plans. Our continuing employee education program keeps our team up to date on current codes, products and processes to facilitate the permit and plans approval processes in the various cities and counties where we work.

Our plumbing engineers work with the field and material team to expedite any issues that may cause delay to the project or work with vendors to ensure correct selection of material types, pumps and interceptors to meet the client’s needs.

FABRICATION

.

Our fabrication process is the backbone of our business.

Once a job is designed, cut sheets that precisely list all materials included for the project are developed from the isometric drawings, material is collected from existing inventory, and fabrication begins. Fabrication efforts takes place at our Carson facility in a multi-shift production level environment. ABS, cast iron, copper, CPVC, Pex, CSST and black pipe are cut and assembled for all of the project’s waste, storm, water and gas systems.

PACKAGING & DELIVERY

.

Completed pre-fab assemblies are packaged and delivered.

Once a production run is completed, the fabricated material assemblies are subjected to strict quality control, packaged and delivered to the job site per pre-determined production schedules across California from the San Francisco bay area in the north, San Diego in the south, and Riverside/Inland Empire area in the east. Numerous heavy equipment logistics support assets are used to support operations including over 10 delivery trucks, four Freightliner Tracker-Trailers with 40-foot trailers and rear mounted Moffatt forklifts for optimum delivery and staging of fabrication pallets and four Pettybone 5-ton forklifts.

BUILD & INSTALLATION

.

Our installers work with the pre-fabricated project.

At the job site, our plumbing systems experts productionize their efforts and work with the fabricated product and the associated ISOs and cutsheets to build the job. This effective process allows a higher level of quality control and an optimum level of cycle and process time efficient installation.

CUSTOMER SERVICE

.

We maintain the product for one year after installation.

As part of our contract, we will provide Customer Service for all projects up to one year after completion. Support staff in our office is available by telephone and Superintendents, Foremen, and Technicians are available throughout our territories. Three fully stocked and equipped Customer Service Vans are available 24 hours a day for immediate quality response to any crisis or emergency.

Latest Projects

AMPAM serves its primary customers, apartment developers in the Southern and Central California markets, from our Wilmington headquarters in Los Angeles County.

View ProjectsCareers

AMPAM Parks Mechanical offers exceptional career opportunities that will allow you to make an immediate impact within the organization. We'd like to hear from you.

Learn MoreQuestions?

For any information on upcoming projects, employment opportunities or to get in touch with customer service, you may call 310-835-1532 or reach us through email at our contact page.

Contact Us